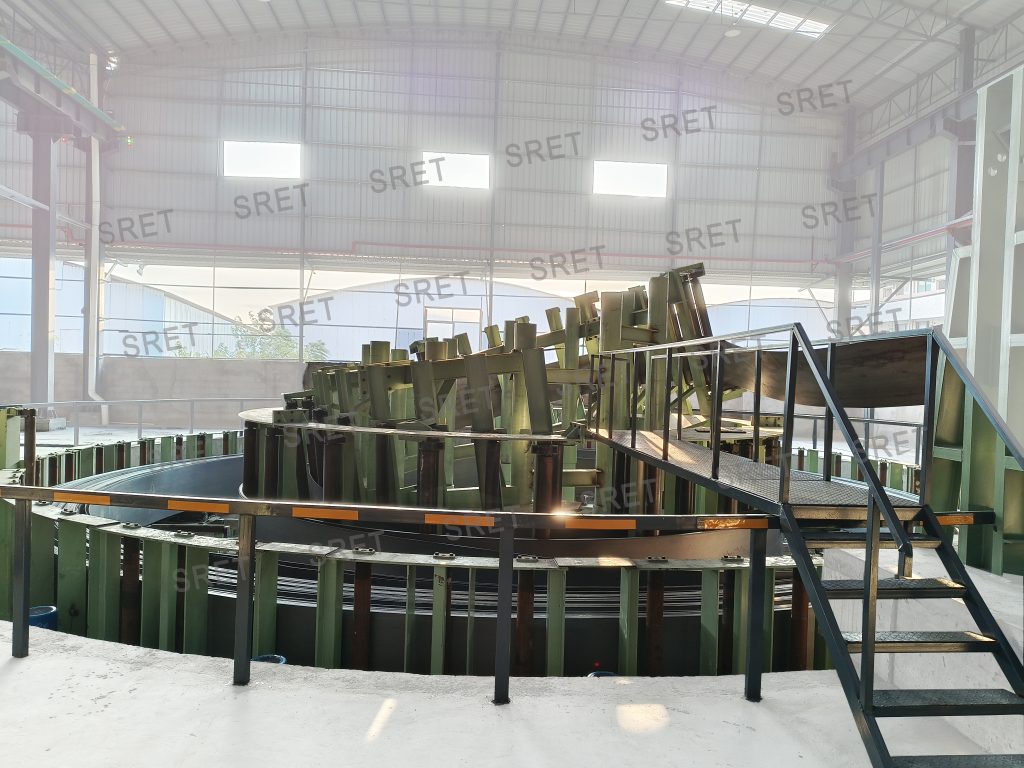

In the manufacturing industry, efficiency and precision are paramount, especially in processes involving horizontal spiral accumulator. These innovative devices play a crucial role in strip processing lines, ensuring smooth material flow and reducing downtime.

Horizontal spiral accumulators are designed to manage strip movement seamlessly, enhancing production line performance. By storing excess strip during line stoppages and feeding it back during operation, these accumulators maintain continuous production flow.

1.Enhanced Production Efficiency: By mitigating stoppages and optimizing strip handling, horizontal spiral accumulator significantly enhances overall production efficiency.

2.Space Optimization: These devices are compact and integrate seamlessly into existing production lines, maximizing floor space utilization.

3.Reduced Material Waste: Precise control over strip movement minimizes material waste, contributing to cost savings and sustainability efforts.

When integrating a horizontal spiral accumulator into your production line, ensure compatibility with existing equipment and consider regular maintenance to maximize uptime and longevity. Proper alignment and periodic checks are essential to prevent issues and ensure continuous operation.

In conclusion, leveraging a horizontal spiral accumulator can revolutionize your strip processing operations. From enhancing efficiency to minimizing material waste, these devices offer substantial benefits in modern manufacturing environments. Incorporate this advanced technology to streamline your production processes and stay ahead in today’s competitive market.

For more insights on optimizing your strip handling with a strip accumulator, contact us today to discuss your specific needs and explore tailored solutions.