In modern manufacturing, precision and efficiency are paramount. For industries requiring precise cutting and material handling, cold saw flying cut off systems and horizontal spiral accumulators are two crucial components. These technologies help streamline processes and ensure high-quality outcomes, whether in metalworking, pipe production, or other precision-based operations. This blog will explore the advantages of these systems and how they contribute to improved productivity.

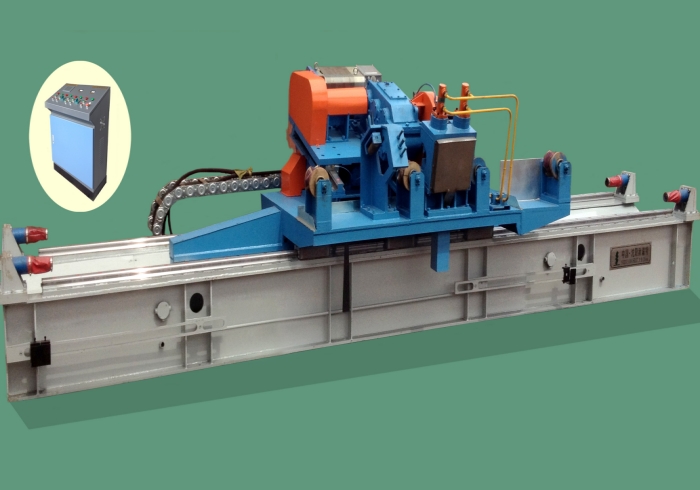

A cold saw flying cut off is a specialized cutting system that combines a cold saw with high-speed cutting capabilities. It is commonly used in industries such as metalworking, steel production, and pipe manufacturing.

A horizontal spiral accumulator is a material handling system designed to store and manage materials in a compact and efficient manner. This system is often used in conjunction with cutting systems like the cold saw flying cut off.

Integrating both cold saw flying cut off and horizontal spiral accumulators into a production line can significantly improve operational efficiency and product quality.