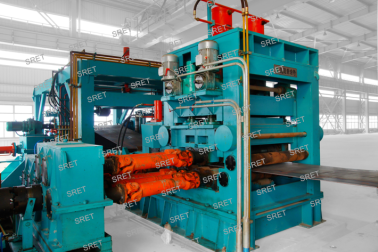

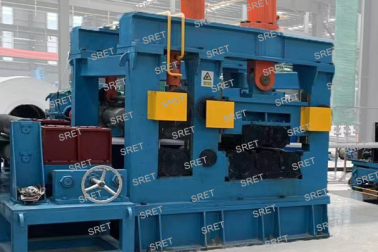

Flattener is applied to level the head and tail of the coil. The coil head and tail, after being leveled, are fed onto shear end welding machine to be sheared and butt welded.

The electrically adjustable center aligning vertical rolls at the entrance of flattener adjust the strip coming from uncoiler, to ensure the strips are center aligned. After the clutches being engaged, the motor driven pinching rolls guide the strip onto leveling rolls. Flatteners can be designed with structures of either 5 rolls or 7 rolls (2 mobile top rolls and 3 stationary bottom rolls for 5 rolls structure, 3 top mobile rolls and 4 stationary bottom rolls). The hydraulic actuated top rolls drop to compress tightly the strip, and both top and bottom rolls or top rolls rotate driven by inverter based AC motor, to level the strip with the compression force of top and bottom rolls, and to feed it to the next work process, shear end welding.

| Model No. | Strip Width (mm) | Strip Thickness (mm) | Speed (m/min) | Roll Qty. |

| JP32 | 40 – 120 | 0.6 – 1.6 | 15.0 | 5(7)rolls |

| JP50 | 60 – 200 | 1.0 – 3.5 | 12.0 | 5(7)rolls |

| JP76 | 100 – 260 | 1.2 – 3.75 | 12.0 | 5(7)rolls |

| JP89 | 100 – 300 | 2.0 – 4.0 | 12.0 | 5(7)rolls |

| JP114 | 120 – 400 | 2.0 – 5.0 | 12.0 | 5(7)rolls |

| JP165 | 160 – 520 | 2.5 – 7.0 | 12.0 | 5(7)rolls |

| JP219 | 240 – 700 | 3.5 – 8.0 | 8.0 | 5 rolls |

| JP273 | 320 – 900 | 4.0 – 10.0 | 6.0 | 5 rolls |

| JP325 | 300 – 1100 | 5.0 – 12.7 | 6.0 | 5 rolls |

| JP406 | 600 – 1300 | 6.0 – 14.0 | 6.0 | 5 rolls |

| JP508 | 700 – 1650 | 6.0 – 16.0 | 6.0 | 5 rolls |

| JP630 | 900 – 2000 | 6.0 – 20.0 | 6.0 | 5 rolls |

| JP660 | 900 – 2200 | 6.0 – 23.0 | 6.0 | 5 rolls |

| JP711 | 900 – 2400 | 8.0 – 25.0 | 6.0 | 5 rolls |