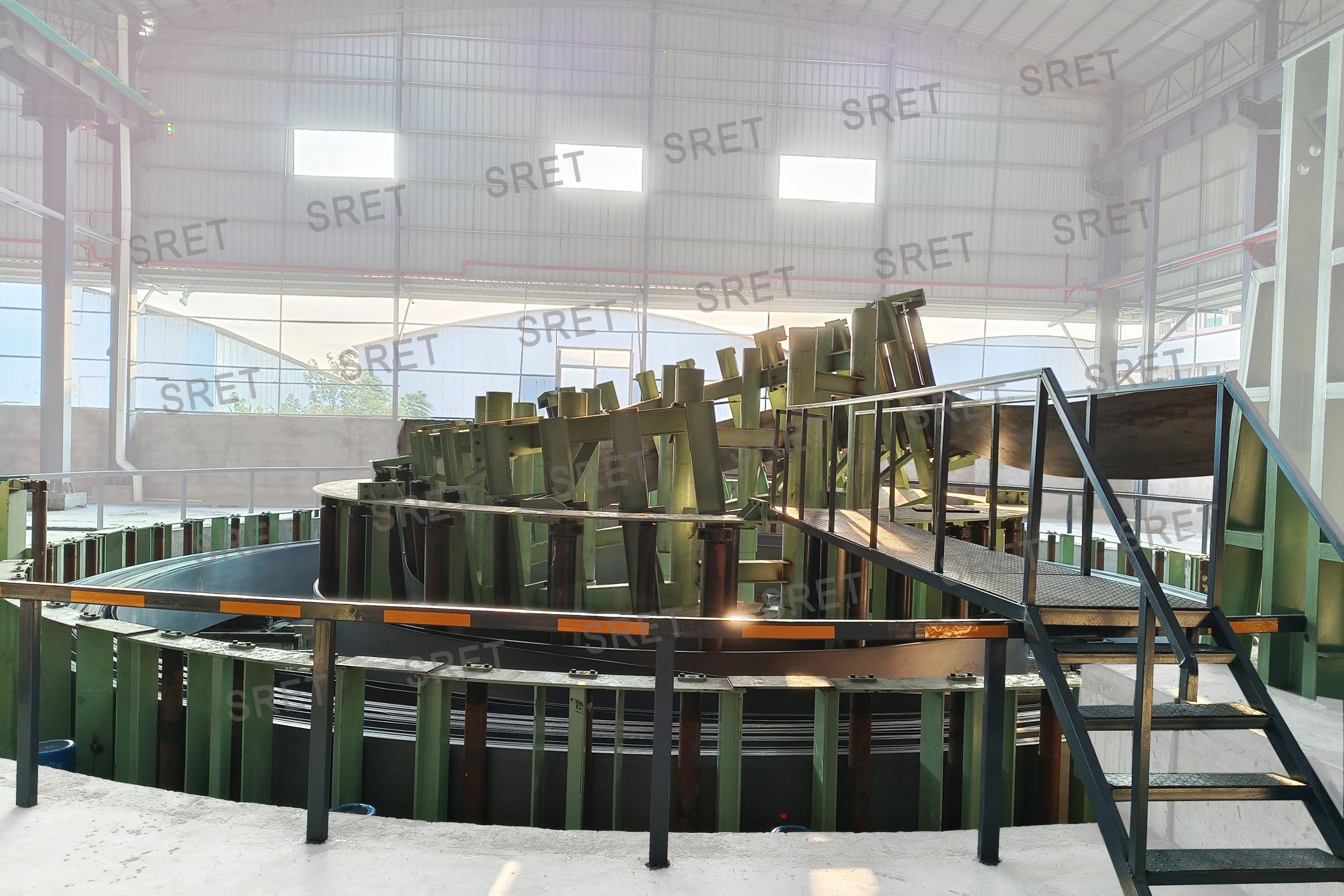

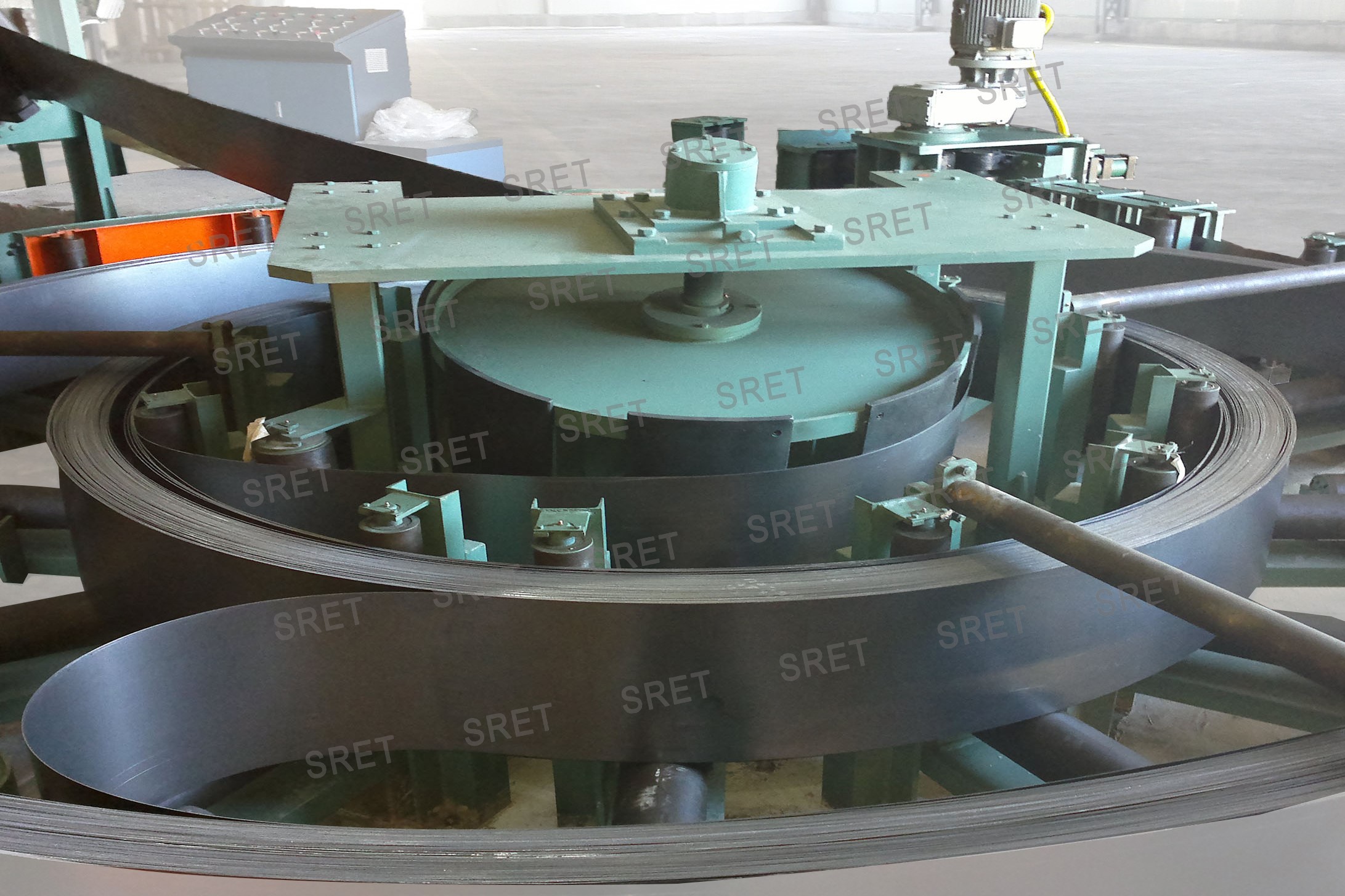

Tabletop accumulator adopts the structure of strip’s entry from outer and exit from center and the storage method of variable number of loops. Horizontal roller accumulator adopts the structure of strip’s entry from outer and exit from center and the storage method of variable-or fixed-number of loops. Horizontal spiral accumulator adopts the structure of strip’s entry from outer and exit from center and the storage method of fixed number of loops.

For the first time, the strip passing from the inlet twist stands is driven by the hydraulically actuated pinching rollers, onto the accumulation rollers, being stored in forms of inner and outer loops. As the strip is fed onto accumulator, the number of strip loops and subsequently the total length keep increasing. When it reach a designed number of loops, the pinching roll stops, but the strip continue to be driven by powered rollers, to feed into storage, till it reaches the designed full capacity. The strip is passively pulled out by powered forming mill, to exit from the central spiral roll track, and then pass through outlet de-twist roll stands that turn the strip horizontally before entering forming mill. The work process sequence is the follows: strip fast fill-in when the fill-in speed faster than strip exit speed; the storage reach full when the fill-in speed equal or less than exit speed; the accumulator constantly supply strip to the non-stop tube mill line when one coil is finished filling in, until filling-in of the next coil starts. The above described work process is carried out repeatedly to ensure a continuous operation of tube mill line.

Horizontal spiral accumulator adopts centralized chain or individually separate drive with modes of stop, high-speed fill in, synchronized speed with tube mill, and jog. It is equipped with the features of empty and full storage detection and alarming, as well as remote monitoring.

| Model No. | Strip Width (mm) | Strip Thickness (mm) | Storage (m) | Fill-in Speed(m/min) |

| WLHT32 | 40 – 100 | 0.6 – 1.6 | 400 – 1200 | Max. 300 |

| WLHT50 | 60 – 160 | 0.6 – 2.0 | 400 – 1200 | Max. 300 |

| WLHT76 | 100 – 240 | 1.0 – 4.0 | 400 – 1000 | Max. 300 |

| WLHT89 | 110 – 280 | 1.5- 5.0 | 400 – 900 | Max. 180 |

| WLHT114 | 120 – 400 | 1.5 – 6.0 | 400 – 900 | Max. 180 |

| WLHT165 | 160 – 520 | 2.0 – 7.0 | 400 – 800 | Max. 160 |

| WLHT219 | 240 – 700 | 3.0- 8.0 | 350 – 800 | Max. 170 |

| WLHT273 | 320 – 900 | 3.0 – 10.0 | 300 – 800 | Max. 120 |

| WLHT325 | 500 – 1100 | 5.0 – 12.7 | 300 – 800 | Max. 120 |

| WLHT406 | 600 – 1300 | 6.0 – 14.0 | 300 – 800 | Max. 120 |

| WLHT508 | 700 – 1650 | 6.0 – 16.0 | 300 – 800 | Max. 100 |

| WLHT630 | 900 – 2000 | 6.0 – 20.0 | 300 – 800 | Max. 100 |

| WLHT660 | 900 – 2200 | 6.0 – 23.0 | 300 – 800 | Max. 100 |

| WLHT711 | 900 – 2400 | 8.0 – 25.0 | 300 – 800 | Max. 100 |