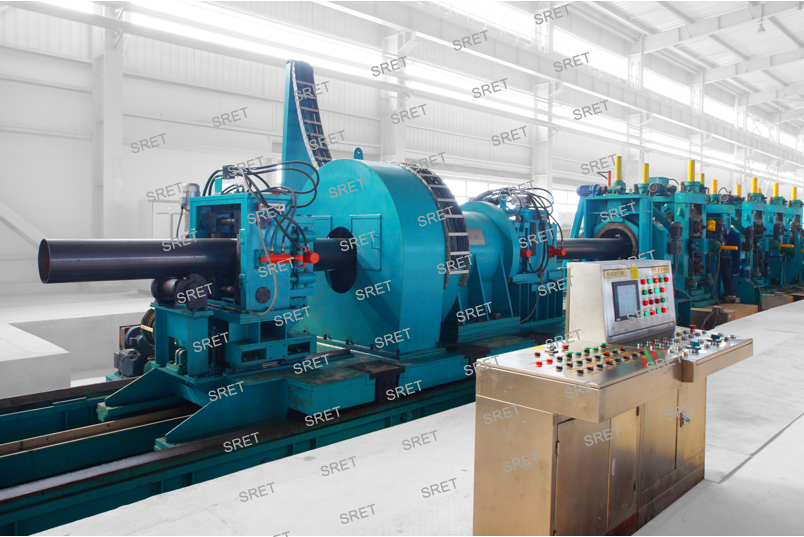

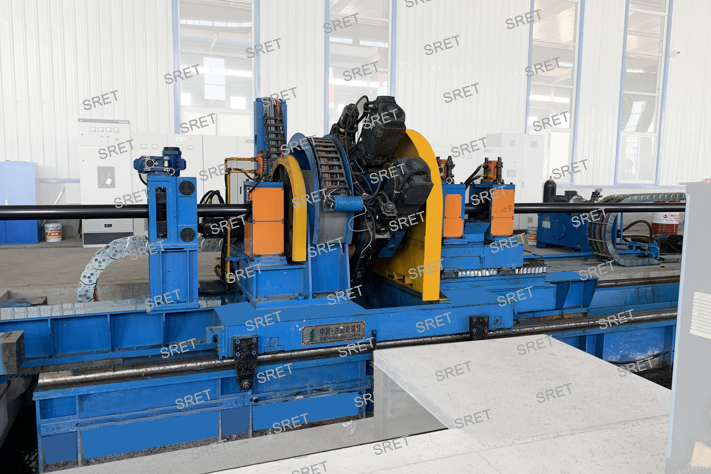

CNC orbital milling type cold saw cut off is a new-generation high-tech equipment on ERW tube mill line. It’s able to cut on line in form of milling the medium and large tube products accurately into pre-set cut length, with the results of a beautiful cutting surface of smooth and burr free.

Orbital milling type cold saw cut off can be designed in terms of the type of saw blade feeding path, in the form of either polar coordinate or rectangular coordinate, for more suitability and performance for varied shape of tubes.

When the tube from the sizing mill comes to the cold saw flying cut off, it runs on a speed measuring roll. A photoelectric encoder installed on it measures and converts the speed and length of the running tube into pulse electronic signals and transmits them to the motion control system. While receiving the instruction signals from the control system, the traveling carriage powered by either AC servo or DC motor and driven via a rack and pinion mechanism, starts accelerating to track the running tube. The carriage reaches the speed of the tube mill line, and then remains synchronization. When the pre-set cut length is reached, the clamping fixtures installed on the carriage clamp the running tube, actuated hydraulically or pneumatically. The two sawing blades installed on a rotating table of polar coordinate profiling feeding system or on sliding tables of rectangular coordinate profiling feeding system are powered by spindle servo motors and custom designed reducer. The feeding of them is compound movement of φ (center angle) rotational and r (radius) radial, or X-axis horizontal and Y-axis vertical and carried out through the guidance of ball screw and linear guide mechanism driven by servo motors, which enable a cross-section profile milling cut. Upon the completion of cutting, the clamps open, the travelling carriage instructed by the motion control system quickly decelerates and stops, and all the feeding and sawing systems and travelling carriage return to the original position or status, and wait for the next work cycle.

Orbital milling type cold saw cut off operates via a reliable numeric motion control system and realize a completely automated on-line cutting. Its work process sequences are: traveling carriage acceleration, synchronous track, clamp, cut off, and quick return to the original position. Once programmed, milling type orbital cold saw cut off is able to work completely automatically at an unmanned mode. The saw blade can be eight TCT or HSS.

| Model No. | Tube Size (mm) | Thickness (mm) | Length (m) | Tolerance (mm) | Speed (m/min) |

| XFJ130 |

Ø 48 – 130 □ 50 – 150 |

2.5 – 8.0 | 4.0 – 15.0 | ≤ ±2 | Max. 70 |

| XFJ165 |

Ø 48 – 165 □ 50 – 180 |

2.5 – 10.0 | 4.0 – 15.0 | ≤ ±2 | Max. 70 |

| XFJ219 |

Ø 114 – 219 □ 60 – 200 |

3.5 – 12.0 | 4.0 – 18.0 | ≤ ±2 | Max. 60 |

| XFJ273 |

Ø 165 – 273 □ 60 – 220 |

4.0 – 12.7 | 4.0 – 18.0 | ≤ ±2 | Max. 40 |

| XFJ325 |

Ø 165 – 325 □ 80 – 250 |

5.0 – 14.0 | 4.0 – 18.0 | ≤ ±2 | Max. 40 |

| XFJ406 |

Ø 219 – 406 □ 80 – 300 |

6.0 – 16.0 | 4.0 – 18.0 | ≤ ±2 | Max. 35 |

| XFJ508 |

Ø 219 – 508 □ 100 – 400 |

6.0 – 18.0 | 4.0 – 18.0 | ≤ ±2 | Max. 30 |

| XFJ630 |

Ø 219 – 630 □ 100 – 400 |

6.0 – 20.0 | 4.0 – 18.0 | ≤ ±2 | Max. 30 |

| XFJ660 |

Ø 325 – 660 □ 100 – 500 |

6.0 – 22.0 | 4.0 – 18.0 | ≤ ±2 | Max. 30 |

| XFJ711 |

Ø 325 – 711 □ 100 – 600 |

8.0 – 22.0 | 4.0 – 18.0 | ≤±2 | Max. 25 |

| XFJ762 |

Ø 325 – 762 □ 100 – 600 |

8.0 – 25.0 | 4.0 – 18.0 | ≤±2 | Max. 25 |