In the manufacturing and processing industries, efficiency and smooth operation are crucial. To enhance production capabilities and streamline processes, businesses are turning to advanced equipment like the custom strip accumulator and the horizontal spiral accumulator. These sophisticated systems are designed to optimize material handling and improve overall productivity. Let’s delve into the benefits of each and how they can revolutionize your operations.

A custom strip accumulator is a specialized piece of equipment designed to handle and manage strips of material, often used in metalworking, paper processing, and other industries. Here’s why investing in a custom strip accumulator can be a game-changer:

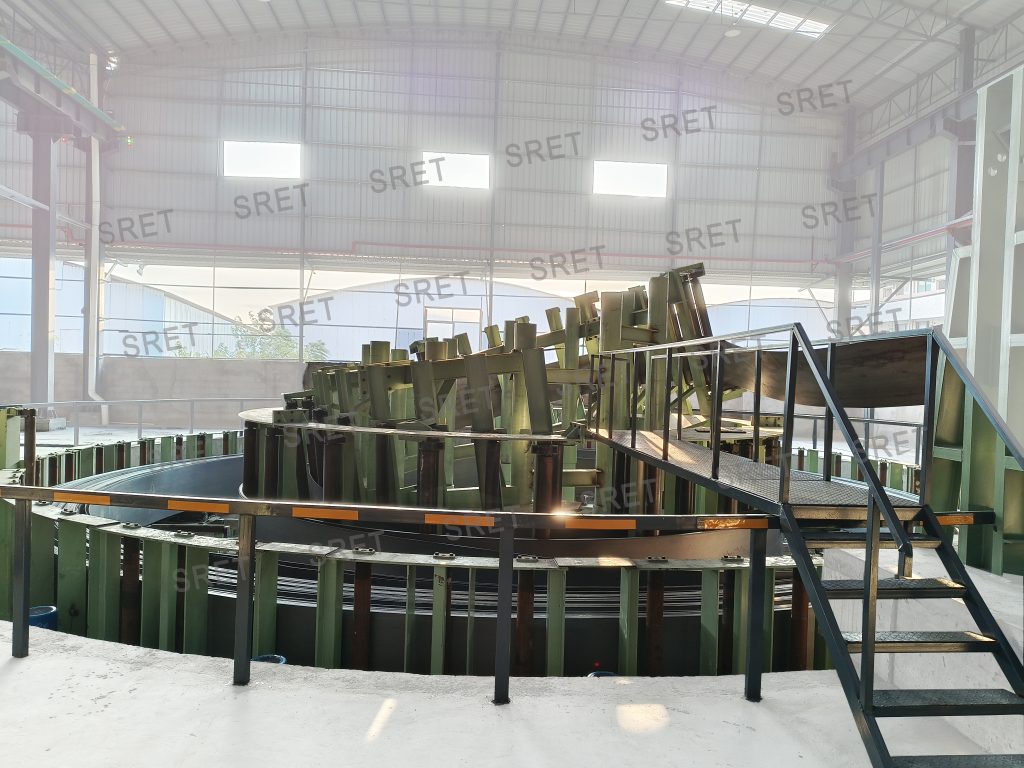

The horizontal spiral accumulator is another innovative solution for material handling, offering unique advantages that complement those of the custom strip accumulator:

Space-Saving Design

The horizontal spiral accumulator features a compact spiral design that optimizes vertical space. Unlike traditional linear accumulators, this system requires less floor area while still accommodating a large volume of materials. This is particularly advantageous for facilities with limited space.

Integrating both a custom strip accumulator and a horizontal spiral accumulator into your production line can provide a comprehensive solution for material handling. The custom strip accumulator efficiently manages material strips, while the horizontal spiral accumulator optimizes space and ensures smooth material flow. Together, these systems enhance productivity, reduce downtime, and improve overall operational efficiency.

Investing in advanced equipment like the custom strip accumulator and the horizontal spiral accumulator can significantly improve your manufacturing processes. These systems offer tailored solutions, efficient material handling, and space optimization, contributing to a more streamlined and cost-effective production line. By leveraging the strengths of both accumulators, businesses can achieve greater operational efficiency and maintain a competitive edge in their respective industries.